About Us

Our Journey Through Time

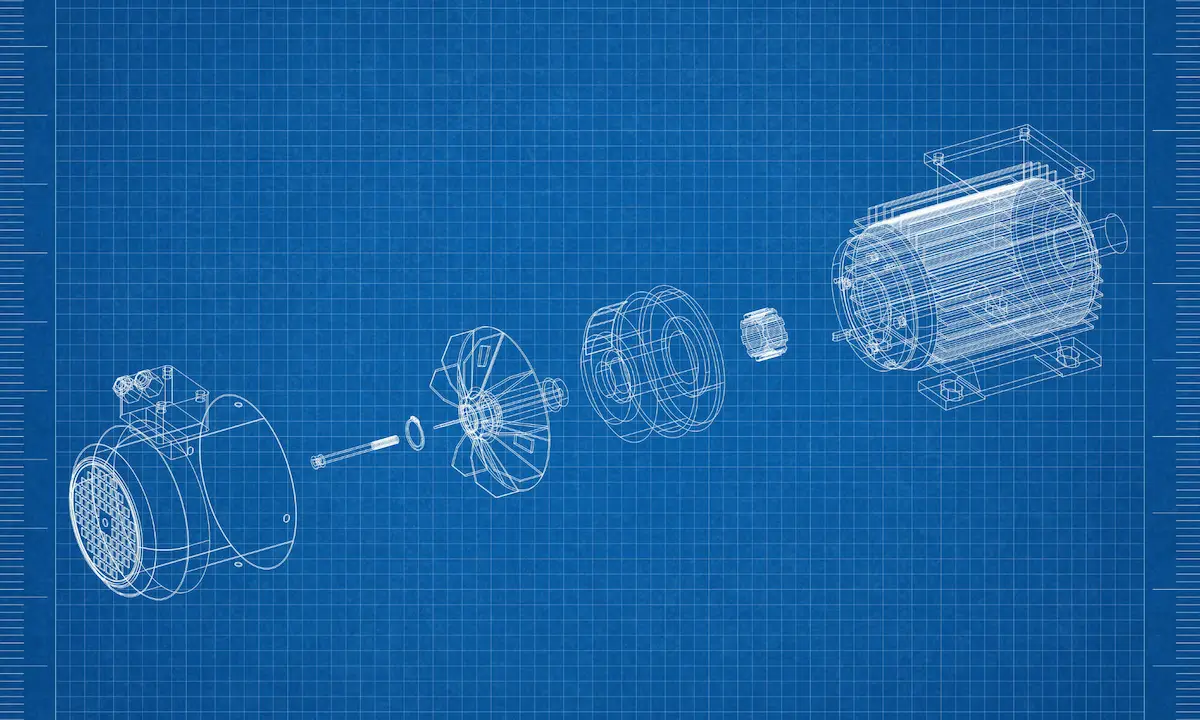

Established in 1994, ACDC Winding embarked on a journey of growth, transforming into a beacon of success within the industry. Over the years, our dedication and meticulous management have shaped us into a trusted name, known for delivering unparalleled service to our clients.

Roots and Growth

The first goal set was to invest in the testing facilities in the factory, although ACDC Winding already had a fantastic service history on motors we want to improve on a constant basis. A new Risatti surge tester was purchased and recently we also added a Megger/Baker 6kV tester to our test bay.

As with most businesses in South Africa, ACDC Winding also suffered production setbacks due to lack of basic service delivery with electricity and water supply. ACDC Winding purchased and installed 2 x back up generators and also installed back up water systems. ACDC Winding is now able to operate at full production capacity during loadshedding and water interruption cycles.

Our new management team and staff are constantly looking for new ways to grow the organisation and to work smarter. We are all exited to see what the future will hold in terms of new technological advances.

Our Competitive Edge

What sets us apart? It’s our unwavering commitment to excellence. With over 50 years of collective industry knowledge, we’re not just experienced; we’re experts.

Our fleet of six delivery vehicles, meticulously monitored for real-time response, ensures that your needs are met swiftly and efficiently.

From efficient turnaround times to top-tier expertise, quality products, and competitive pricing, ACDC Winding is your partner for success.

Our Workshop Facilities

-

Factory floor area 1200m2

-

5t overhead crane

-

2t spray booth crane

-

1,5t dipping crane

-

Carpentry Shop

-

Steam Clean Area

-

De-Carbonising Tank

-

Horisontal Press

-

Inspection Tables

-

Controlled Burnout Ovens

-

Core Tes / Re-stack

-

Coil Machines

-

Controlled Curing Oven

-

2 x Backup Generators

-

2 x 6Kv Surge Testers

-

Backup Water System